Vintage Air University

One of the most misunderstood and underappreciated components in any automotive drive train is the engine accessory drive system. The accessory drive system operates often at rotating speeds even higher than the engine’s crankshaft. No matter how well-built or powerful your engine may be, the engine accessory drive is its life support system.

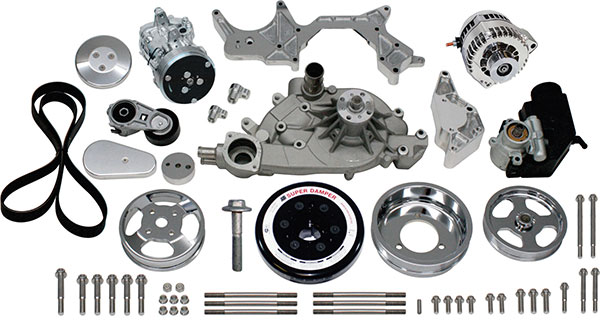

174014 LS Drive Shown

The Strongest Drive System You can Buy!

Back in1994, we set out to test the performance of our air conditioning systems in the most demanding way we knew. That project was the “Cool 200” Studebaker. The goal was simply to run the long course at Bonneville at over 200 mph AND make all the runs with a standard Vintage Air system delivering reliable, cool comfort the whole time. As it turned out, the air conditioning system was the easy part. Building an engine accessory drive system to survive 1000 horsepower at 249 MPH became the real challenge.

At that time, no off-the-shelf products, including the OEMs, could handle the job. So we first turned to racing component suppliers for advice.NASCAR engines routinely run near that power load and for long, hard miles. But race cars are not usually air conditioned. And free-running water and oil pumps don’t produce the kinds of harmonic vibration a cycling air conditioner compressor can introduce into the drive system. We knew we had to engineer our own solution, and that was the birth of the Front Runner engine drive systems.

The performance industry standard has always been to hang the accessories such as alternator, power steering pump and air conditioner compressor from the engine’s existing mount holes wherever possible using simple flat steel brackets. These brackets do provide mounting for the components, but often looked less than attractive. In fact, we manufacture steel bracket kits, and they offer a low-cost method of installing the engine drive components. But these conventional brackets can limit the choices of intake systems, exhaust options, and make deck-height machining problematic. And today, the introduction of modern engines such as the GM LS Series and the Ford Coyote modular engines requires an integrated mounting approach.

That is what the Front Runner drive systems are all about. By eliminating all mounting points beyond the engine block itself and designing a super-compact component package, we now overcome any intake, exhaust or cylinder head option problems. By specifying a more compact compressor and alternator, plus standardizing to a high-performance water pump, we create the smallest drive package ever available. The bonus to you is making your engine swap much easier because of improved clearances all around. And the final, and most important benefit, is that Front Runner brackets are designed to become an integral part of your engine’s block. A solid, totally rigid platform that virtually eliminates the kind of harmonic vibration that can destroy a conventional engine drive bracket.

We produced the first Front Runner system for testing in 1998. We then installed them into our own hot rods and ran them for thousands of miles from coast to coast, proving our ideas and tweaking them until they were perfect. Only then did we offer them to the public. Over the past 17 years, the Front Runner has proven to be one of our most successful products.

While the term “Front Runner” has been used to describe drive systems offered by other companies, no other system is equal. The Front Runner was engineered from the start for maximum Performance First! These are not appearance or dress-up components. They are the essence of “form following function.” Performance first is not just a slogan, it is our whole way of life at Vintage Air!