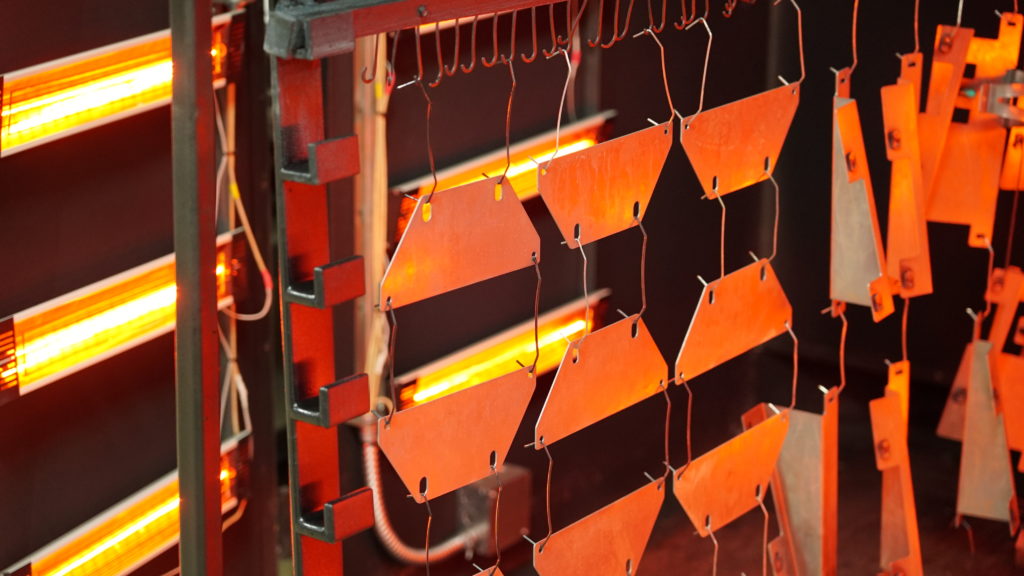

Vintage Air’s new pre-treatment process provides a longer lasting and more durable powder coating to ensure only the highest quality product makes it to consumers.

Vintage Air, the leading manufacturer of complete performance air conditioning systems for street rods, sport trucks and performance cars, has designed a new pre-treatment process for its in-house powder coating. The result is a far superior product than preceding finishes.

When looking for new ways to improve the finish on Vintage Air products, taking the powder coating process in-house was the first step. Rather than doing a quick wipe down in preparation for powder coating, putting the materials through an extensive pre-treatment process primes the raw surface for a smooth and sturdy finish. Hubbard-Hall, the leader in chemical products for surface finishes, was the first place we looked for help when designing the formula for the new pre-treatment solution.

The new process was created by Vintage Air’s manufacturing engineering team, led by Senior Chemical Process Engineer, Allison Chisenhall-Harding, who is also the daughter of owner and founder of the company, Jack Chisenhall.

Chisenhall-Harding integrated three of Hubbard-Hall’s advanced cleaning products to create the new process. “These off-the-shelf solutions resulted in substantial cost savings and quality improvements when compared to alternate pre-treatments we considered, such as other methods of chemical and mechanical processing,” Chisenhall-Harding said. The multi-step process dips the parts through each of the three chemicals before the powder coating is applied.

The new pre-treatment process helps the powder coating better adhere to the metal by stripping it of any contaminants that may interfere with the bonding process. This helps to achieve a more refined end result that is stronger and more durable.